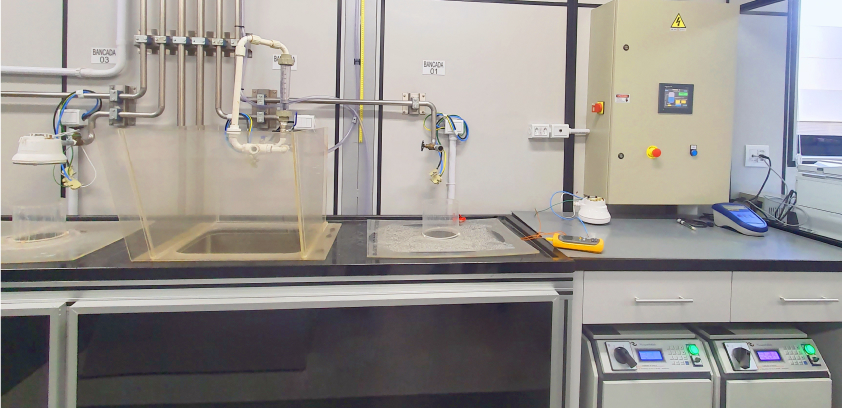

Polymeric Material Laboratory

This laboratory is equipped with:

• Spectrophotometer: performs the registration of color patters, as well as the evaluation of color variations of parts in the process.

• Moisture Content Analyzer: checks moisture content of polymeric materials (pellets), making it possible to check the moisture levels of the polymers arriving at the company, as well as the working condition of dehumidifiers installed in the manufacturing facilities.

• Densimeter: used to analyze the density of materials. Through it, we check the differences in material densities for the same product, in order to check for variations.

• Accelerated weathering test: used to evaluate the ability of polymers against weathering, such as condensation, rain and UV light. This test is applied for comparisons between materials, blends and additives used in the process, as well as for the evaluation of the quality of lots of Anti-UV additives incorporated in our products.